We are involved on an industrial activity with high technical complexity addressed to a segment from the first transformation level implemented to a later drawing step.

We are specialised in manufacturing special aluminium based alloys on wire rod format to be used in different mechanical, electrical and welding applications. The wire rods are produced on coils with a weight up to 2.5 t.

| Metallurgical Series | Main elements | Typical Alloys* | Applications | Additional information |

|---|---|---|---|---|

| 1xxx | High Purity Al | 1070 – 1090 – 1199 – 1100 | Metallizing & electronics |

BROCHURE TECHNICAL SAFETY COIL |

| 2xxx | Al Cu | 2014 – 2017 – 2024 – 2117 | Aeronautics & automotive | |

| 3xxx | Al Mn | 3003 - 3103 | Automotive & air cooling systems | |

| 4xxx | Al Si | 4018 - 4020 - 4032 - 4043 - 4046 - 4047 | Welding & Additive Manufactoring | |

| 5xxx | Al Mg 1 - Al Mg 3,5 Al Mg > 3,5 |

Any alloy <3,5 Mg 5005-5019(US 5056)-5050-5051-5052-5087-5154-5183-5186-5249-5356-5554-5556-5754 |

Mechanical & Welding | |

| 6xxx | Al Mg Si | 6056 – 6060 – 6061 – 6063 – 6082 – 6101 | Automotive & Electrical | |

| 7xxx | Al Zn | 7050-7075 | Mechanical & Aeronautic | |

| 8xxx | Al Fe - Al Zr | 8076 – 8176 – TAL (AT1) – ZTAL (AT3) | Electrical, Overhead Conductors | |

| *Any other alloy can be produced upon request | ||||

| Technical Specs | ||||

| Chemistry | EN 573-3 or any customer requirement | |||

| Aluminium and Aluminium alloys Drawing Stock | EN 1715-1; EN 1715-2; EN 1715-3; EN 1715-4 | |||

| Temper | EN 515 | |||

| Quality Certificates | EN 10204 (3.1) | |||

|

Coils dimensions (EU/US) standards up to 2,500 kg (5,512 lb) EU - Typical 2000 kg (4409 lb) +/-3% - Inner diameter 560-570 mm (22.047-22.440”) US - Typical 2000 kg (4409 lb) +/-3% - Inner diameter 750-770 mm (29.527-30.315”) Temper: F-HO-O3 |

||||

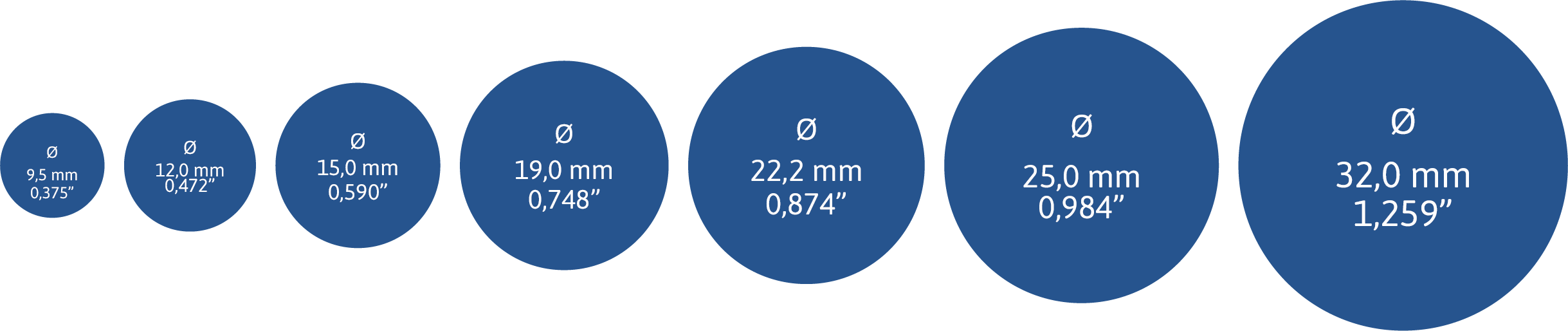

| Rod diameters | (mm) 9.5 – 12.0 – 15.0 – 19.0 – 22.2 – 25.0 – 32.0 | |||

| (inches) 0.375 – 0.472 – 0.590 – 0.748 – 0.874 – 0.984 – 1.259 | ||||

One of the differential characteristics of ESALROD consists in the ability to manufacture wire rod on different diameters, starting at 9.5 mm (0,375 inches) and up to 32.0 mm (1,259 inches).

This versatility of the Continuus Properzi rolling line enables ESALROD to supply the wire industry with thick diameters, in order to meet the early-bird applications on the market, such as machining larger pieces to be used in the automotive and aerospace industries.

Nowadays we are certified on the 4 following ISO standards (9001, 166002, 45001, COVID) and are as well in the certification process of the environmental ISO14001 that is expected to be finished before end of 2021.

SST-0148/2020

SST-0148/2020

ER-0790/2014

ER-0790/2014

IDI-0006/2019

IDI-0006/2019

COV-2020/0089

COV-2020/0089

Our wire rod is cold drawn in order to reduce the section step by step improving in that process the mechanical properties of the alloy.

The final applications our aluminium wire rod after drawing are very diverse, been applied on different sectors and customers worldwide. The automotive, aerospace, electronics and food industries, among many others, are some examples where the alloys come to life on their final uses.